Lean Six Sigma Consulting

Let’s Elevate Operational Performances

Welcome to the pinnacle of operational excellence—Investogen Africa Limited’s Lean Six Sigma Consulting. As seasoned experts in business process optimization, we seamlessly integrate Lean and Six Sigma methodologies to revolutionize your operations and maximize value across industries.

Our Methodology: The Fusion of Lean and Six Sigma

At Investogen Africa Limited, we understand that the integration of Lean and Six Sigma is the key to unlocking unparalleled efficiency. Our methodology as lean manufacturing consultants strategically merges traditional Lean principles with Six Sigma tools, creating a dynamic approach that caters to the unique needs of your business. Key Components:

We pinpoint high-potential opportunities by focusing on critical areas such as Overall Equipment Effectiveness (OEE). This targeted approach ensures optimal resource allocation for maximum impact.

Recognizing that waste reduction is a universal imperative, we deploy Lean tools judiciously. Our consultants apply the right tools based on your current strategy, the value at stake, and the front line’s ability to adopt them.

Driving Success Through Strategic Deployment

Lean Six Sigma consulting improves business processes by increasing efficiency, minimizing waste, and improving manufacturing quality. Our processes aim to identify areas for improvement and then implement tailored strategies to address them.

Lean Six Sigma FAQ

Lean Six Sigma consulting improves business processes by increasing efficiency, minimizing waste, and improving manufacturing quality. Our processes aim to identify areas for improvement and then implement tailored strategies to address them.

What Are the Principles of the Investogen Africa Limited Lean Methodology Approach?

We’ve built our lean methodology around the following core principles to drive efficiency and operational excellence:

● Continuous improvement

● Demand-driven pull-based systems

● Employee empowerment

● Flow optimization

● Standardization

● Value Identification

● Value Stream Mapping

● Waste elimination

We have designed these principles to help clients reduce costs, increase productivity, and create a more agile and responsive operation.

What Sets Six Sigma Apart from Lean?

While Lean focuses on eliminating waste and improving flow, Six Sigma is centered on reducing variability and defects through statistical analysis. Lean Six Sigma combines these approaches, enabling organizations to address both efficiency and quality challenges simultaneously.

What Are the Key Benefits of Six Sigma?

● Improved process consistency through defect reduction.

● Enhanced customer satisfaction via improved quality standards.

● Data-driven decision-making to identify and solve root causes.

● Greater competitiveness through continuous performance monitoring.

What Are the Key Benefits of Lean?

● Increased operational efficiency by streamlining workflows and reducing waste.

● Enhanced agility through the implementation of pull-based systems and optimized processes.

● Improved employee engagement and productivity with empowerment-focused initiatives.

● Cost savings achieved by eliminating non-value-adding activities and enhancing resource utilization.

● Sustained performance improvements driven by a culture of continuous improvement and adaptability.

What Are the Responsibilities of a Lean Manufacturing Consultant?

A lean manufacturing consultant’s responsibility is to guide clients through lean six sigma processes to optimize their operations. Our Lean Six Sigma consulting duties include:

● Assessments: Conducting on-site assessments to identify inefficiencies, bottlenecks, and sources of waste.

● Change management: Fostering a continuous improvement culture and improving communication to facilitate organizational change. Developing internal capabilities and behavioral practices for long-term change and sustainment.

● Implementation Expertise: Leading the execution of tailored Lean Six Sigma solutions with precision, ensuring seamless integration into daily operations while minimizing disruptions and maximizing immediate and long-term value.

● Continuous improvement advocacy: We support continuous improvement by encouraging a mindset of ongoing refinement and adaptability. This helps ensure practices evolve with the business.

What Are the Lean Responsibilities?

● Conducting Value Stream Mapping (VSM) and workflow assessments to identify inefficiencies.

● Implementing Lean tools such as 5S, Kaizen, and Kanban to optimize workflows and eliminate waste.

● Promoting cultural transformation and employee engagement for sustained improvements.

What Are the Six Sigma Responsibilities?

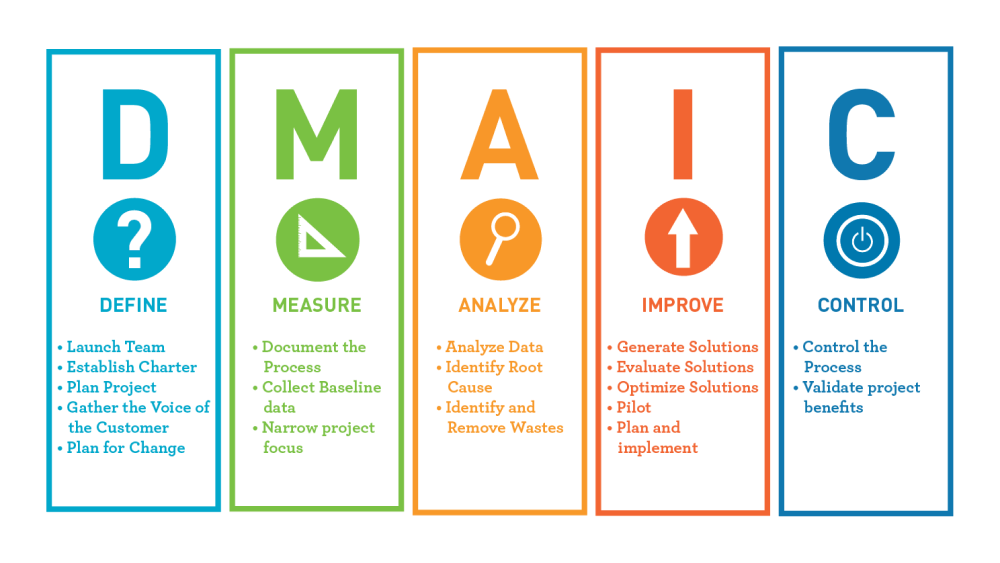

● Using statistical tools like DMAIC (Define, Measure, Analyze, Improve, Control) to address defects and variability.

● Conducting detailed Root Cause Analysis using tools like Pareto Charts and Fishbone Diagrams.

● Developing and implementing process control systems to sustain quality improvements.

● Training employees to use Six Sigma tools like Control Charts and Process Capability Analysis for ongoing monitoring.

What Approach Does Investogen Africa Limited Use To Implement Lean Manufacturing Solutions for Clients?

At Investogen Africa Limited, we use a signature Identify, Innovate, and Implement framework to bring about real and lasting organizational change. Our approach drives efficiency, eliminates waste, and creates value for each customer.

● Identify: Our Lean Six Sigma consulting begins with a comprehensive analysis of each client’s current operations using tools such as Value Stream Mapping to identify areas for improvement. This may be inefficiencies, sources of waste, or production bottlenecks. The main focus of this stage is gaining a full understanding of strategic goals and uncovering performance gaps that interfere with reaching them.

● Innovate: An innovation approach used customized Lean Six Sigma solutions to develop a roadmap for successful adaptation. Tools may include statistical analysis, 5S, Kaizen, Kanban, and Just-in-Time to align with the needs and industry of each client. We encourage employee engagement to grow buy-in and adaptation. Controlled trials of initiatives help to validate their effectiveness before full-scale implementation.

● Implement: A comprehensive implementation process ensures a smooth and successful transformation. Our process includes making Lean Six Sigma processes part of daily operations, hands-on training for leadership, supervisors, and front-line workers, and establishing real-time monitoring systems for KPI tracking.

Through our Identify, Innovate, and Implement methodology, Investogen Africa Limited ensures that lean manufacturing solutions not only address immediate challenges but also deliver sustainable improvements for long-term operational excellence.

What Industries Can Benefit From Lean Six Sigma Consulting?

Any industry that seeks improvements in its operational processes can benefit from Lean Six Sigma consulting. Our clients include manufacturers, oil and gas companies, transportation and logistics providers, mining operations, and utility providers. Common examples include:

● Manufacturing: Reducing production defects and improving throughput.

● Oil & Gas: Streamlining maintenance operations and optimizing asset reliability.

● Transportation & Logistics: Enhancing supply chain efficiency and reducing delivery delays.

● Mining: Improving equipment reliability and operator performance.

● Utilities: Enhancing process standardization and minimizing downtime.

Success in Lean Six Sigma isn’t just about tools; it’s about deploying them strategically. Investogen Africa Limited’s approach to lean process improvement consulting aligns the right tools, at the right time, with the right people. This ensures a high degree of success and sustainment in the optimization journey.

Lean Expertise Across Industries

At Investogen Africa Limited, our Lean expertise extends across a diverse spectrum of industries, positioning us as the go-to partner for transformative operational enhancements. We recognize the universal impact of Lean principles, acknowledging their power to reduce waste, enhance productivity, and amplify throughput across varied business landscapes.

Unleashing the Power of Lean: Reducing Waste, Amplifying Productivity

In manufacturing, Lean principles can revolutionize production processes by minimizing downtime, optimizing workflow, and eliminating unnecessary steps.

The mining sector benefits from streamlined operations, reduced equipment waiting times, and improved physical availability. In the oil & gas industry, Lean strategies increase throughput by eliminating unnecessary steps, enhancing equipment utilization, or increased OEE. Regardless of the industry, Investogen Africa Limited’s Lean experts tailor solutions that align with the unique challenges and opportunities each sector presents.

Reasons to Engage Investogen for Lean Transformations

Prospective clients should reach out to Investogen Africa Limited for Lean improvements when seeking to optimize operational efficiency, reduce costs, and stay ahead in an increasingly competitive market. Our Lean experts are ready to collaboratively identify and implement transformative solutions that align with your strategic goals, ensuring sustained success across industries.

Six Sigma Excellence Across Industries

Investogen Africa Limited stands at the forefront of Six Sigma excellence, offering a versatile application of this methodology across a diverse range of industries. Our commitment to precision and data-driven decision-making empowers organizations to elevate quality standards, reduce defects, and achieve sustained excellence in their operations.

Unlocking Potential with DMAIC: A Universal Problem-Solving Approach

The DMAIC (Define, Measure, Analyze, Improve, Control) process, a hallmark of Six Sigma, serves as our universal problem-solving compass.

In manufacturing, DMAIC helps identify and rectify defects in production processes, ensuring a consistently high-quality output. In the financial sector, it aids in optimizing transactional processes, reducing errors, and enhancing overall accuracy. From healthcare to technology, DMAIC’s versatility allows Investogen Africa Limited to target diverse opportunities for improvement with a structured and effective approach.

Reasons to Choose Investogen for Six Sigma Transformations

Prospective clients seeking to elevate their quality standards, reduce defects, and foster a culture of continuous improvement should turn to Investogen Africa Limited for Six Sigma transformations. Our expertise, combined with the universally applicable DMAIC process, ensures that organizations achieve tangible and sustainable improvements, regardless of their industry.

Committed to Excellence

Our team of experts is ready to help you develop strategies for not only surviving, but thriving in the future.

View our Case Studies

You May Also Be Interested In

Contact Us

Contact us to find out how our business process optimization services can benefit your company